- Hogar

- Equipo

- Industrias

- Nosotros Immay

- Recurso

- Contacto

| Estado de Disponibilidad: | |

|---|---|

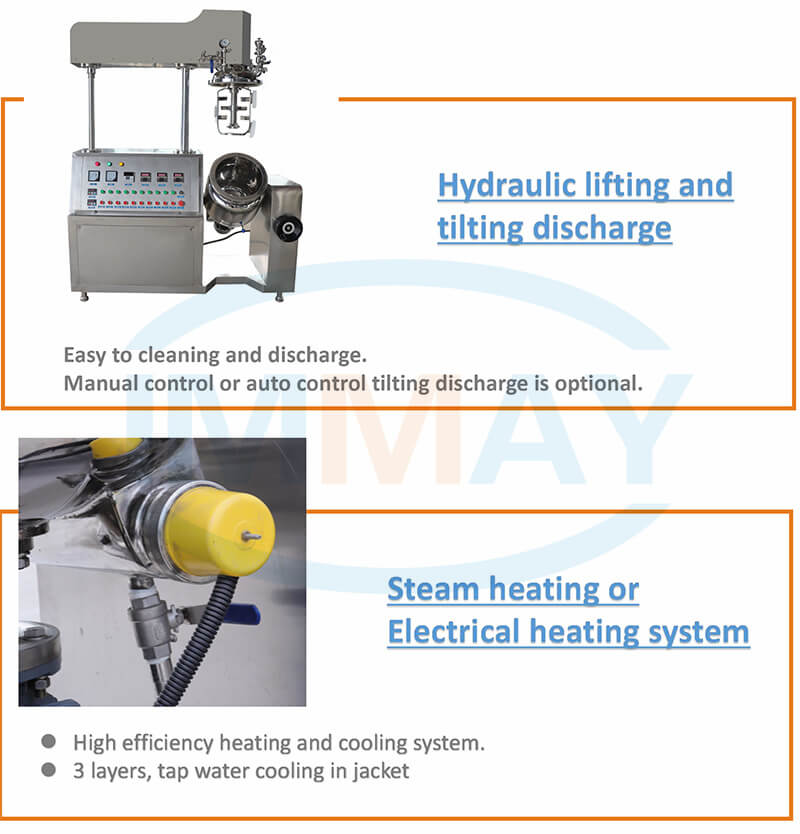

Hydraulic Lifting Vacuum Homogeneous Emulsifying Mixing Vessel is a high quality equipment developed by our company in combination with international and domestic advanced technology. It is suitable for the production of viscous materials such as lotion, foundation, toothpaste, cream and so on. Its outstanding advantage is that under the dual action of the homogenizer and the agitator paddle, the material can be well fused, so that the material can be completely emulsified.

Performances and Features

1. Vacuum homogenizer emulsifier is professionally designed for cream/paste producing, with advanced homogenizing technology.

2. Vacuum homogenizer mixing machine is composed of water tank, oil tank, vacuum emulsifying tank, vacuum pump, hydraulic system, discharge system, electric control system and working platform etc.

3. The vacuum homogenizer machine lifting systems include single-cylinder lifting and double-cylinder lifting. Various high quality products can be customized according to customers’ requirements.

4. The vacuum mixer and reactor adopts famous brand frequency converter for speed adjustment, which can meet different technological demands.

5. The vacuum defoaming makes materials up to aseptic request.

Model | Effective Capacity | Homogenizer | Mixing | Dimension (mm) | Heating(KW) | Limited Vacuum (Mpa) | |||||

Power | Speed | Power | Speed | Length (mm) | Width (mm) | Height (mm) | Electric heating | Steam heating | |||

IMA-5S1B | 5L | 0.37 | 0~3000 | 0.18 | 0~63 | 1260 | 540 | 1600/1850 | 5 | 2 | -0.09 |

IMA-10S1B | 10L | 0.55~0.75 | 0~3000 | 0.37~0.55 | 0~63 | 1300 | 580 | 1600/1950 | 6 | 3 | -0.09 |

IMA-30S1B | 30L | 1.1~2.2 | 0~3000 | 0.55~0.75 | 0~63 | 1800 | 1000 | 1750/2300 | 18 | 9 | -0.09 |

IMA-50S1B | 50L | 2.2~3 | 0~3000 | 0.75~1.1 | 0~63 | 2430 | 1230 | 1850/2600 | 18 | 9 | -0.09 |

IMA-100S1B | 100L | 3~5.5 | 0~3000 | 1.1~1.5 | 0~63 | 2800 | 1500 | 2000/2750 | 32 | 13 | -0.09 |

IMA-200S1B | 200L | 4~7.5 | 0~3000 | 1.5~2.2 | 0~63 | 2800 | 1850 | 2300/3300 | 45 | 15 | -0.09 |

IMA-300S1B | 300L | 5.5~7.5 | 0~3000 | 2.2~3 | 0~63 | 3000 | 1950 | 2400/3450 | 45 | 18 | -0.085 |

IMA-500S1B | 500 | 7.5~11 | 0~3000 | 3~4 | 0~63 | 3300 | 2100 | 2750/3900 | 50 | 27 | -0.08 |

IMA-1000S1B | 1000 | 11~15 | 0~3000 | 5.5~7.5 | 0~63 | 4200 | 3600 | 3250/4800 | 85 | 30 | -0.08 |

Q: Which information shall I offer before getting solution?

A: Which product will you produce?

B: How many liter per batch or per day do you request?

C: Are there other more requests?

Q:Which machine should I choose?

A:It depends on product you make and the formula process, we will offer you tailor-made design.

Q: I am working on a new processing line that don't know much about what I need, how can you support?

A: We have supplied production line equipments to thousands clients in diverse industries within our decade experience, we will tailor-made you equipments that with fit your capacity request and optimize product performance.

Q:How can you control the quality and delivery?

A:Production strictly according to CE / ISO standards.

B:All our machines will be tested before packaging. Wooden packaing is safe during shipping.

Q: How long is your delivery time?

A: Generally it is 15-30 days, depends on production schedule.

Born in Yangzhou, China, Immay is a leading enterprise specializing in R&D, production and sales of equipment in cosmetics, pharmaceutical, food and beverage, daily health products, chemical and other industries.

As a leading manufacturer of cream and liquid processing equipment, we have developed a variety of machines, including reverse osmosis water treatment equipment, vacuum homogenizer mixer, mixing tank, storage tank, filling machine, capping machine, packaging machine and labeling machine..

The spirit of "dedication and excellence" is deeply rooted in the corporate culture of Immay. We focus on professional and meticulous processes and regard quality as soul of our company.

We keep pace with times, explore and innovate, keep up with the pace of industrial intelligent manufacturing, continue to promote technological innovation, continue to research and develop more advanced and better products, and strive to support customers to improve production capacity and increase profits through more efficient and intelligent equipment.

contenido está vacío!